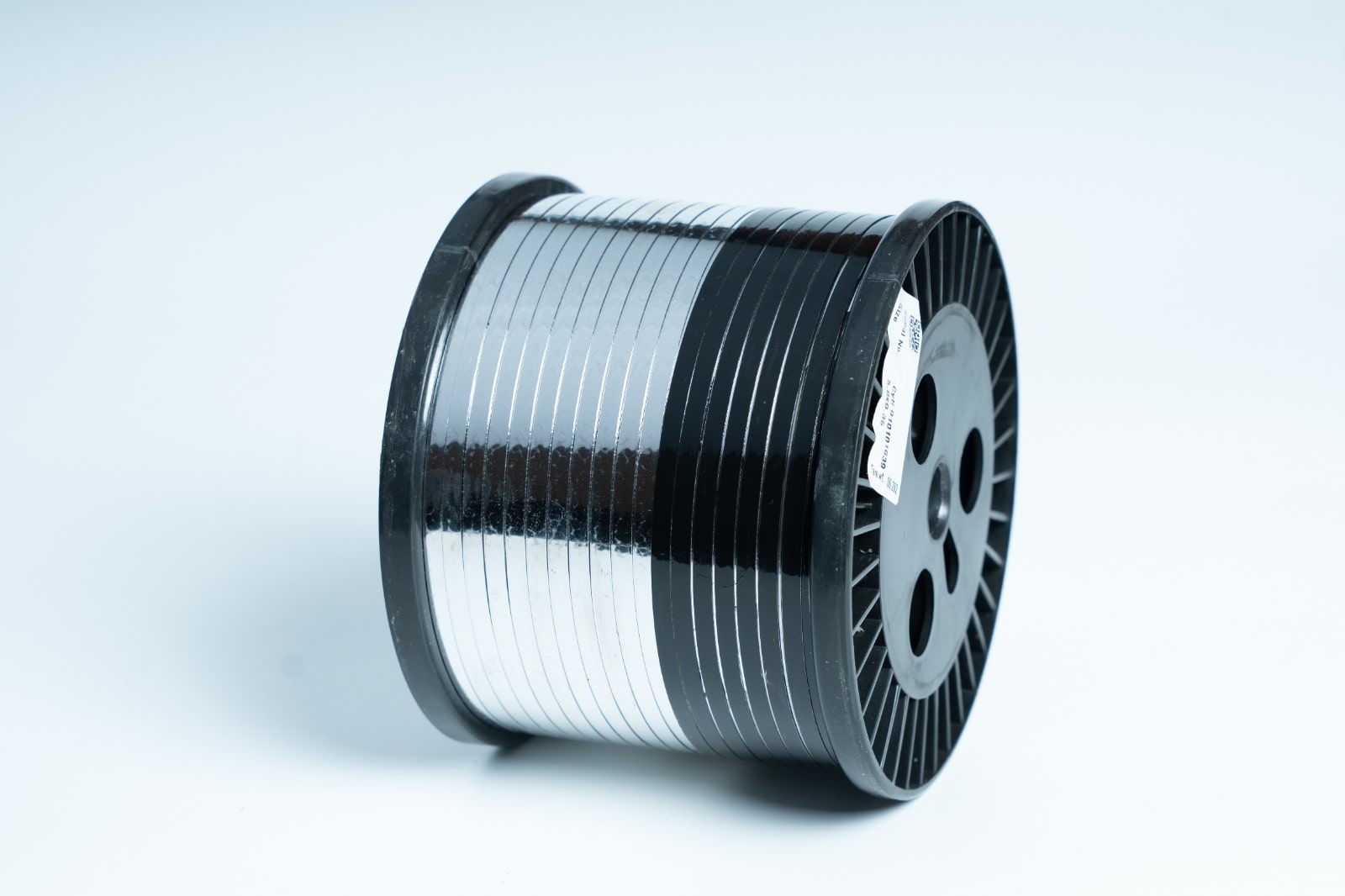

Tinned Copper Interconnect

Tinned copper interconnects also known as Tabbing Ribbon, Solar Wire, Cell Connector, String Connector, PV Ribbon, PV Connect etc. are conductive components made from copper that has been coated with a thin layer of solderable alloys made from various metals such as silver, tin , lead, indium , etc.

These interconnects are used to connect solar cells / strings of solar cells within a solar module, forming electrical pathways for the flow of electricity generated by the cells.

Applications

Tinned copper interconnects are a crucial component in the manufacturing of solar modules. They provide reliable electrical connections between individual solar cells, enabling the modules to efficiently capture and transmit solar energy.

Key Characteristics

Conductivity

Copper is chosen for its high electrical conductivity, allowing for efficient transmission of electricity generated by the solar cells.

Corrosion Resistance

The tin coating on the copper wire provides corrosion resistance, protecting the interconnects from environmental factors such as moisture and humidity, which are common in outdoor solar installations.

Solderability

The tin coating facilitates soldering of the interconnects to the solar cells and other components, ensuring secure and durable connections.

Flexibility

Tinned copper interconnects are designed to be flexible, allowing them to conform to the shape of the solar cells and withstand mechanical stress during the manufacturing process and throughout the lifespan of the solar module.

Temperature Resistance

The interconnects must be able to withstand the temperature fluctuations experienced in solar module operation without compromising their electrical conductivity or structural integrity.

Compatibility

Tinned copper interconnects are compatible with various solar cell technologies and module designs, making them a versatile choice for solar module manufacturers.

Range of Products Manufactured for Poly / Monoperc /Topcon Modules

1. Cell Interconnects

Width: 0.35 mm to 2.0 mm, Thickness: 0.15 to 0.30mm Round: 0.23mm to 0.36 mm

2. Bussing

Width 3mm to 10 mm, Thickness 0.25 mm to 0.5mm

3. LOW TEMPERATURE ALLOYS

Packing Type Cylindrical and Bi Conical 2 Kg to 25 Kgs

4. ALLOY TYPES

Leaded (Sn/Pb)

Lead Free (Sn/Ag), (Sn/Ag/Cu)

Low temperature alloys (Sn/Bi/Pb),(Sn/Bi/Ag),(Sn/Bi)

5. LEADED

6. LEAD FREE

Packing Type

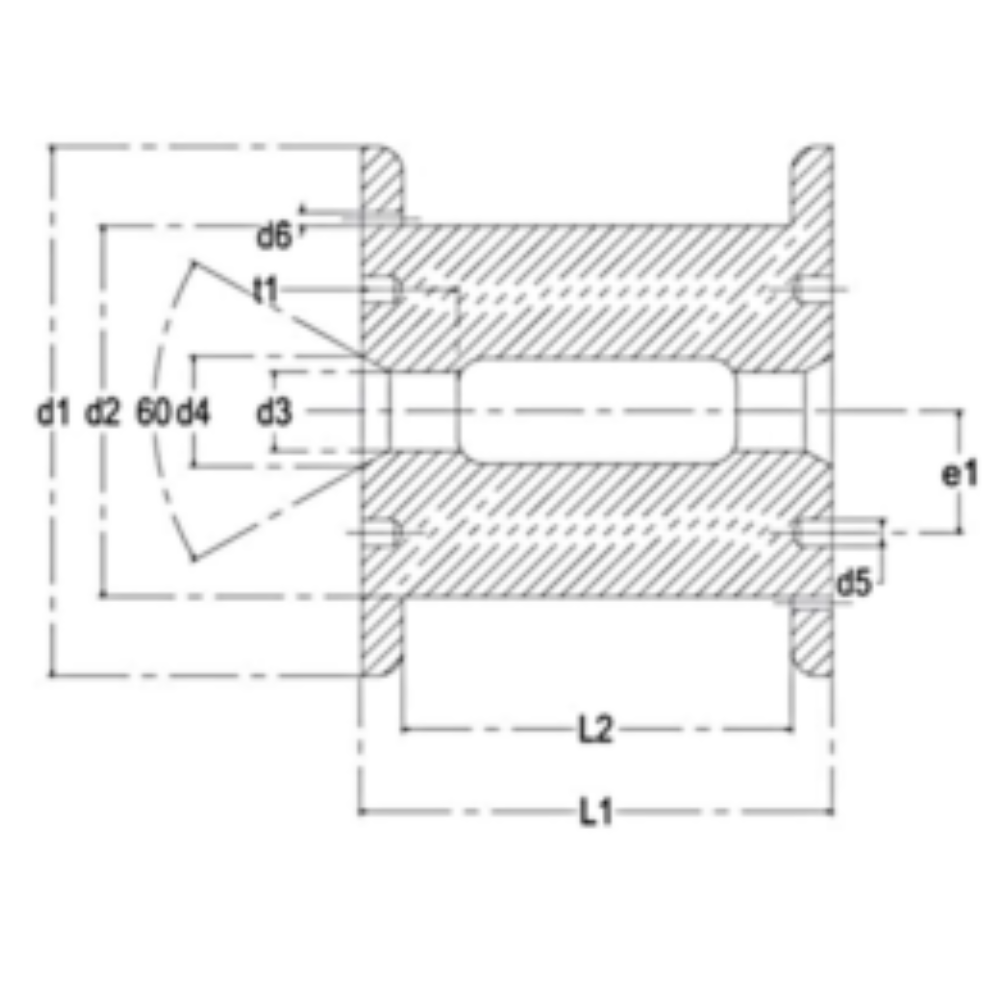

Spool | Type | d1(mm) | d2(mm) | d3(mm) | L1(mm) | L2(mm) | Weight / Spool | Figure Reference |

Cylindrical | P10S | 152 | 100 | 20 | 121.5 | 101 | 5 | A |

Cylindrical | P10S | 152 | 90 | 16 | 122 | 101 | 5 | A |

Ashton Cox | Din 200 | 200 | 125 | 20 | 200 | 160 | 15 | A |

Cylindrical | Din 250 | 250 | 125 | 20 | 250 | 200 | 20 | A |

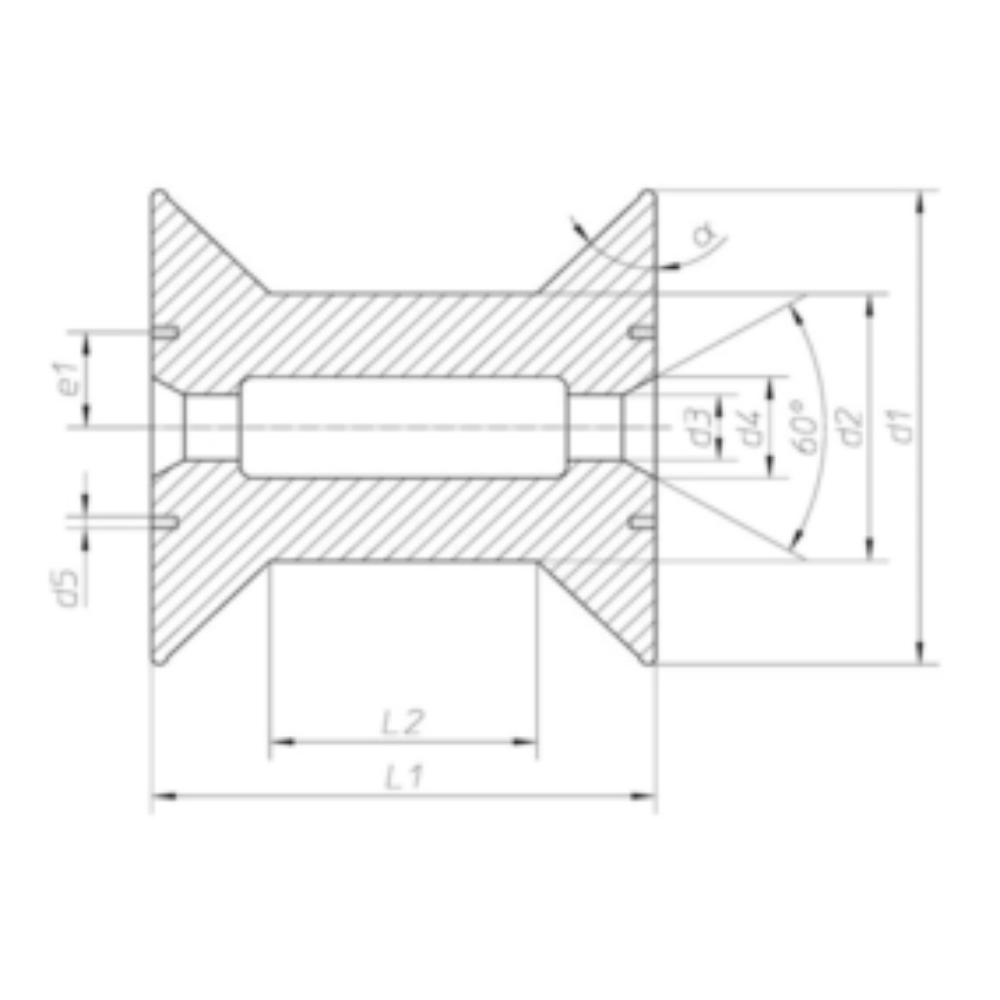

Cylindrical | HKV 160 (IEC) | 160 | 80 | 20 | 160 | 90 | 8 | B |

Bi-Conical | HKV 160 (CN) | 160 | 90 | 16 | 160 | 90 | 8 | B |

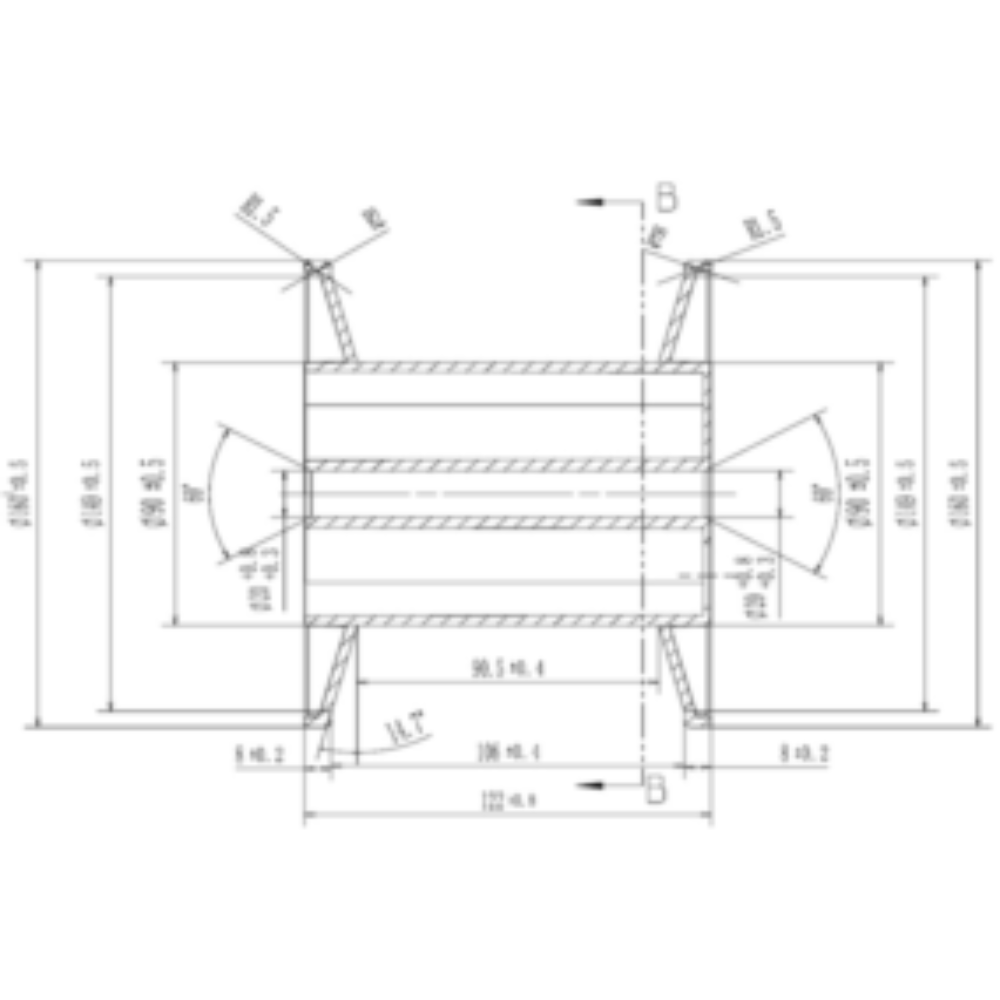

Bi-Conical | PCK160 A (16) | 160 | 90 | 16 | 122 | 90 | 8 | C |

Bi-Conical | PCK 160 A(20) | 160 | 90 | 20 | 122 | 90 | 8 | C |

Bi-Conical | PCK 160 B(16) | 160 | 85 | 16 | 140 | 100 | 10 | C |

Bi-Conical | VCK 160 C(20) | 160 | 85 | 20 | 160 | 120 | 12 | C |