Who we are

Leading the way in Tinned Copper Interconnect Manufacturer and Non-Ferrous Conductors

The journey began in 1980 with our company founder Mr. Vijay Mutha, a first generation businessman starting a small unit for supplying copper conductors to cable and allied companies, and we are the best Tinned Copper Interconnect Manufacturer in India, from the start quality of customer service and product has been at its core values. Over 4 decades Valeo has moved up the value chain of engineering, it leads in special conductors used in upcoming fields like renewable and EV’s.

Pioneering Innovation

Engineered Innovation for Sustainable Copper Wire Solutions

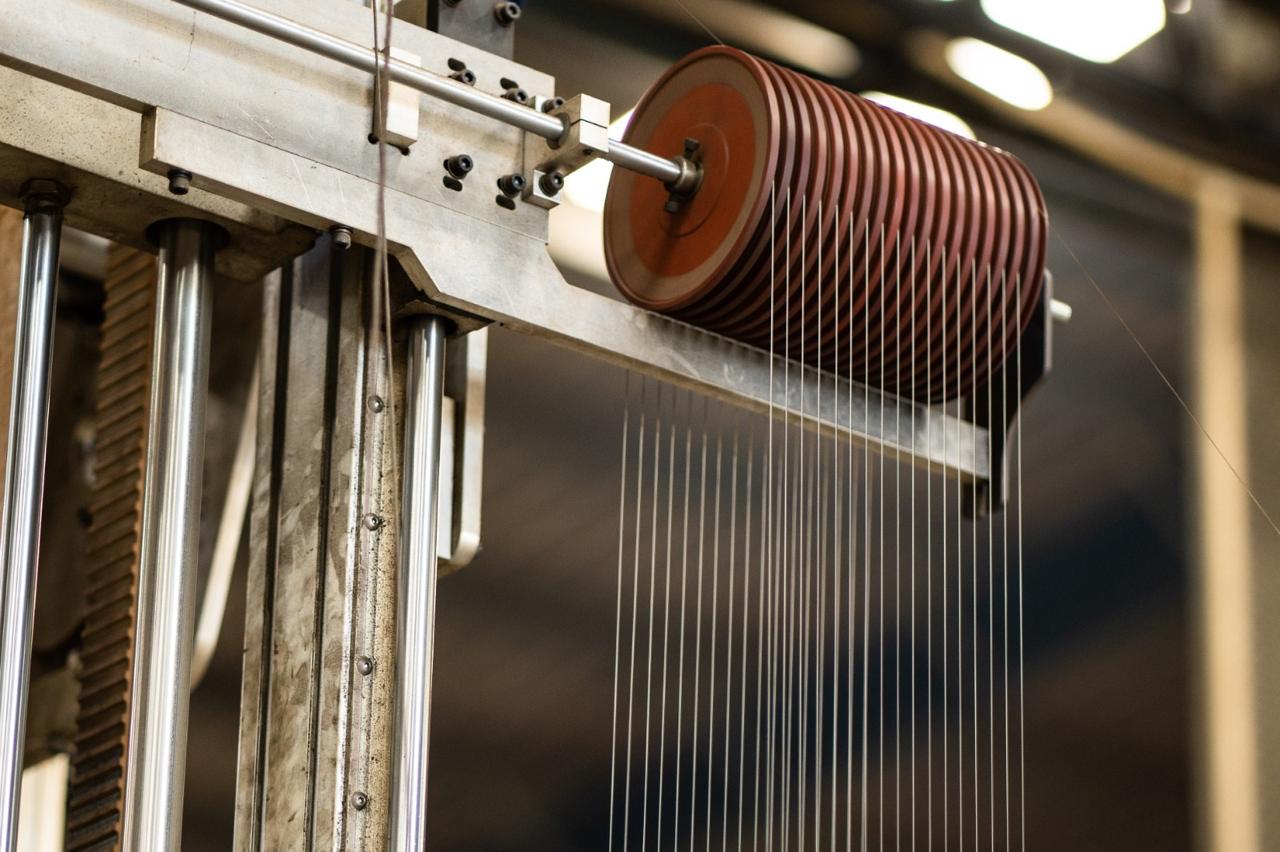

Valeo has a state-of-the-art manufacturing and testing facility, alongside cutting-edge Research and Development team, to deliver engineered innovation in sustainable copper wire solutions for Automotive, Appliances, Power Generation and Distribution and Renewable Energy.

Our Experience

40 Years of Excellence in Custom Copper Wire Manufacturing

We have been manufacturing varied products such as bunched & Stranded. Tin plated, super enamelled copper winding wires (Magnet Wires) for the last 40 years catering to the specific requirements of our customers. We are Leading Tinned Copper Interconnect Manufacturer

Valeo embraces the philosophy of Atmanirbhar (Self-Reliant), striving to excel in cutting-edge and demanding applications such as Space, Defense, Renewable Energy, and Automotive. We are committed to making a significant impact in non-ferrous conductor technology applications. Leading Tinned Copper Interconnect Manufacturer

Time Line of Valeo

Founded the first copper wire drawing plant by first generation Entrepreneur Mr. Vijay Mutha in Hyderabad, doing wire drawing for State Run Hindustan cables.

Grew to the largest copper wire manufacturer in the state of Andhra Pradesh.

Started Magnet wire division to supply magnet wires to upcoming industry of white goods with a capacity of 400 MT per year.

Upgraded to environmental safe manufacturing process a leader in the field and another first in the state of Andhra Pradesh.

Achieved 30% industry supply for fans across India in the organised sector.

Started The Photo Voltaic Division, along with the RE vision for the country developed one of India’s first Photovoltic Line for Interconnect manufacturing.

Achieved 40% industry supply for Solar modules across India.

First Indian Owned Plant to setup Plasmait Technology for production of Photovoltaic Ribbons.

Achived capcity of 500 MW per year supplies to the Photo Voltaic Industry.

Became India’s largest photovoltaic ribbon supplier with over 1GW production capacity.

Grew Capacity to 3 GW per Year.

Trageting to Reach 10 GW production capacity and remain industry leader with innovations for use in Indian module industry.