Magnet Wire

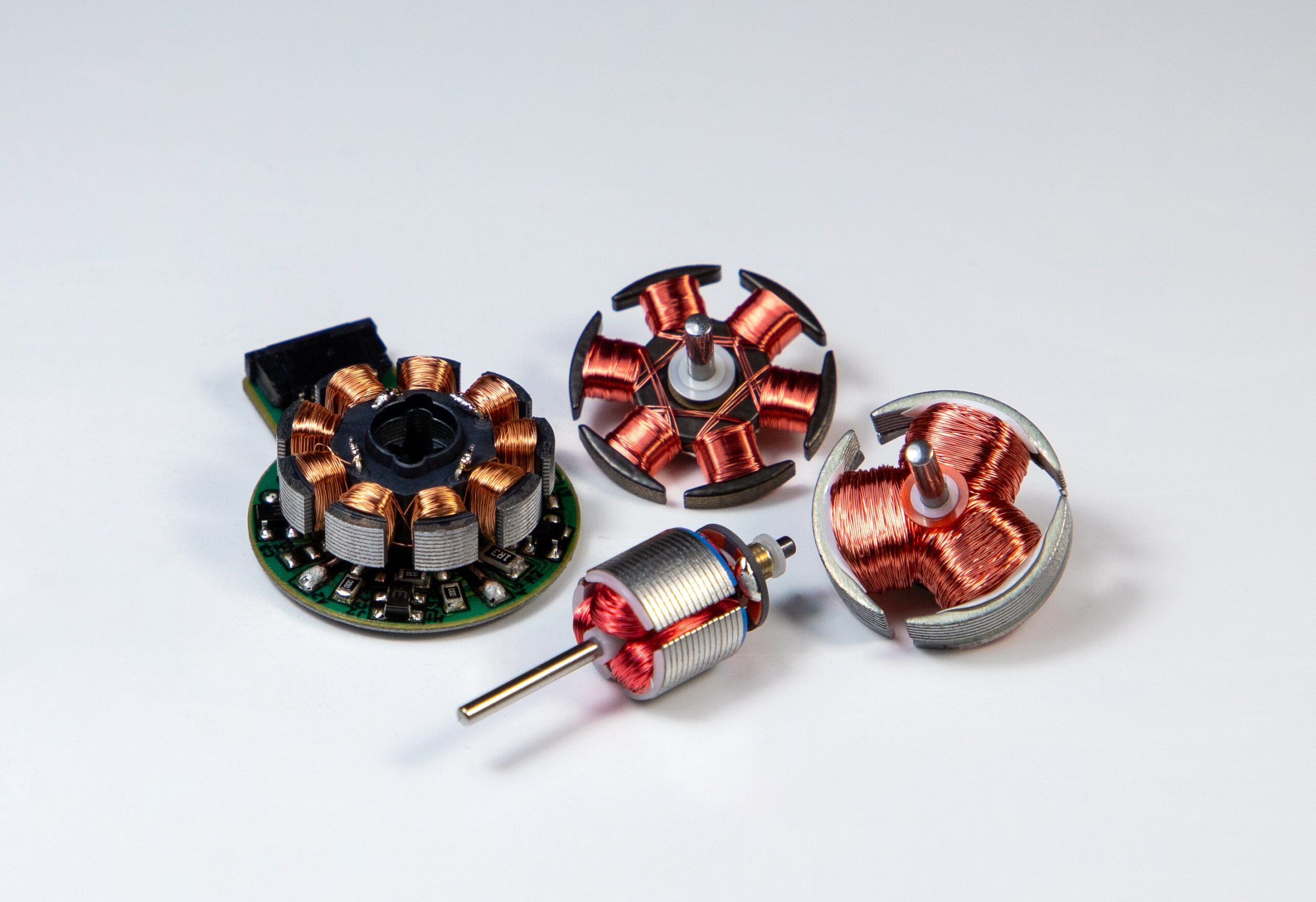

Magnet Wire , also known as winding wire or enamelled wire, is a type of insulated electrical conductor used in various applications requiring the transmission of electrical energy. The application of winding in most cases is where electrical energy is converted to either mechanical energy or heat.

Overall, winding wire plays a critical role in the construction of electrical machinery and equipment, providing a reliable and efficient means of transmitting electrical energy

Applications

Winding wire is commonly used in the manufacturing of electrical motors, transformers, generators, solenoids, and other electrical components. It serves as the primary conductor for carrying electrical current in these devices, for generating the magnetic field.

Key Characteristics

Winding wire is typically made from materials with high electrical conductivity, such as, to minimize energy loss during transmission.

The wire is coated with a thin layer of insulation, often made from enamel or synthetic resins, to prevent short circuits and ensure electrical insulation. We manufacture PE, PU, PEI, PAI and Dual coat variants of magnets wires.

Winding wire comes in various sizes and gauges to accommodate different applications and electrical requirements.

The insulation material used in winding wire is selected based on its temperature rating, ensuring that it can withstand the operating temperatures encountered in specific applications. The temperature class of magnet wires manufactured by us are Deg Centigrade 120 /155 /180/200/220 .

Winding wire is designed to be flexible and easy to wind around coils and bobbins during the manufacturing process.

The wire is engineered to withstand mechanical stress, vibration, and other environmental factors encountered in the operation of electrical devices.

Range of Products Manufactured By Us

Copper

0.08 mm to 2 mm

Aluminum

0.19 mm to 2 mm

CCA

0.1 mm to 1.8 mm

Flat Copper

5 to 30 Sq mm